Common Challenges in Erection Drawings and How to Overcome Them

Key takeaways

- Erection drawings help in the proper assembling of steel buildings.

- Common problem areas include unclear details, dimensional discrepancies, site conflicts, and misunderstandings.

- Erection drawing problems can be avoided with 3D modeling, proper training, and coordination of team members.

- Regular site inspections are necessary to ensure that structures are as designed in the drawings, hence efficient and effective construction.

Erection drawings are elaborate drawings that provide instructions on how to put together the structural components correctly in terms of dimensions, connections, and location. Erection drawings are a critical component of construction and steel structure works. They are used in order to provide a guideline in installing structural elements in the right location.

Nonetheless, these drawings are not always easy to create and interpret. There are a number of obstacles that may influence the effectiveness and precision of construction. Knowledge about these issues and how to overcome them will help to save time, save costs, and have the workflow running smoothly.

Therefore, in the case of companies that provide drafting and detailing services in India, it is essential to deal with these problems to succeed in a project.

Understanding erection drawings

Erection drawings (also known as assembly or installation drawings) are used as a graphic illustration in the construction of a structure. They contain dimensions, locations, and steel components, bolts, and weld specifications. In contrast to general construction drawings, erection drawings are very detailed and precise, and there is minimal room for error.

These drawings are technical, yet they should be easily understood by engineers, fabricators, and site workers. Any failure in clarity may result in construction mistakes, time wastage, and extra expenses.

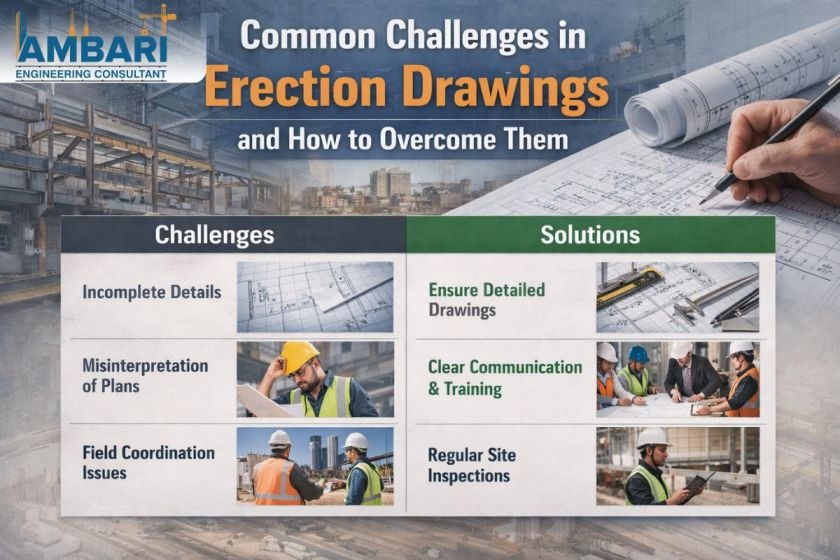

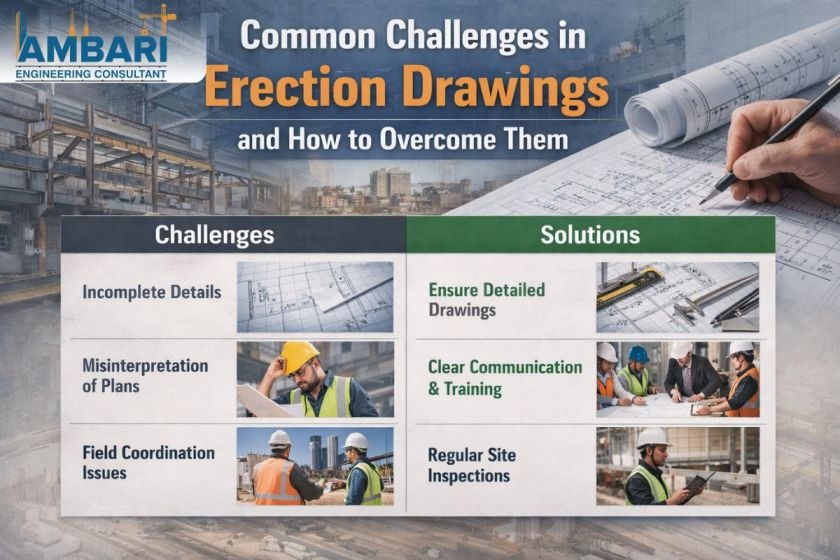

Common challenges in erection drawings

-

Incomplete or ambiguous information

Lack of or vague details is one of the most common issues. In some cases, drawings are not definite about dimensions, materials, or connection types. Such ambiguity may confuse workers and cause errors during the assembly process.

-

Dimensioning errors

Incorrect or inconsistent measurements are another major problem. Even minor dimensioning errors can result in misalignment of steel members, and these mistakes are often costly to fix.

-

Clash with site conditions

Site conditions may not always match the assumptions made in drawings. Foundation irregularities or unexpected obstructions can disrupt steel positioning, especially in renovation or industrial projects.

-

Material and component misalignment

Components may become misaligned or distorted during fabrication or transportation. If these variations are not addressed in erection drawings, on-site adjustments are required, slowing down the project.

-

Lack of communication between teams

Construction involves multiple teams, including designers, engineers, fabricators, and site workers. Poor communication can lead to misinterpretation of erection drawings, delays, and installation errors.

How to overcome these challenges

-

Thorough review and verification

All drawings should be reviewed before starting erection. Comparing dimensions, materials, and specifications helps identify mistakes early and avoids costly on-site corrections.

-

Use of 3D modeling and software tools

Modern software enables detailed steel structure modeling, helping visualize assemblies and detect clashes before fabrication or erection. This approach minimizes errors and improves coordination, especially in steel detailing services in Vadodara.

-

Effective coordination with fabrication teams

Fabrication teams play a key role in executing erection drawings. Regular communication between designers and fabricators helps resolve issues early and prevents delays in component delivery. Fabrication shop drawing services in Vadodara typically maintain close coordination for this reason.

-

Proper training and standardization

Engineers and site workers should be trained to correctly read and interpret erection drawings. Standardizing symbols, notations, and processes across projects reduces confusion and errors.

-

Regular site inspections

Even with accurate drawings, on-site supervision is essential. Inspections at different stages ensure construction matches the drawings and help identify deviations before they become major issues.

Conclusion

Erection drawings play a vital role in successful construction projects, but they are not without their challenges, which include incomplete information, mistakes in dimensions, site clashes, and miscommunication. These problems can be solved with a close examination, 3D modeling, proper coordination, training, and site inspections, which will significantly enhance the results of the project.

However, in the case of professionals offering drafting and detailing services, steel detailing, or fabrication shop drawing services in Vadodara, these approaches are the sure way to make their projects of steel structures accurate, efficient, and cost-effective.

With the knowledge of how to overcome the pitfalls that are common in erection drawings, construction teams are able to save time, minimize mistakes, and produce quality work each time.

Frequently asked questions

-

What are erection drawings?

Erection drawings are detailed specifications that explain how steel structures should be assembled correctly at construction sites.

-

Why do errors occur in erection drawings?

Errors usually occur due to missing details, incorrect dimensions, or lack of communication between teams.

-

How can 3D modeling help?

3D modeling helps visualize structures, identify clashes, and improve accuracy before fabrication and assembly.

-

What role does site inspection play?

Regular site inspections ensure assemblies follow the drawings and help prevent costly construction mistakes.

-

How can coordination between teams be improved?

Coordination improves through frequent communication, standardization, and verification among designers, fabricators, and site workers.