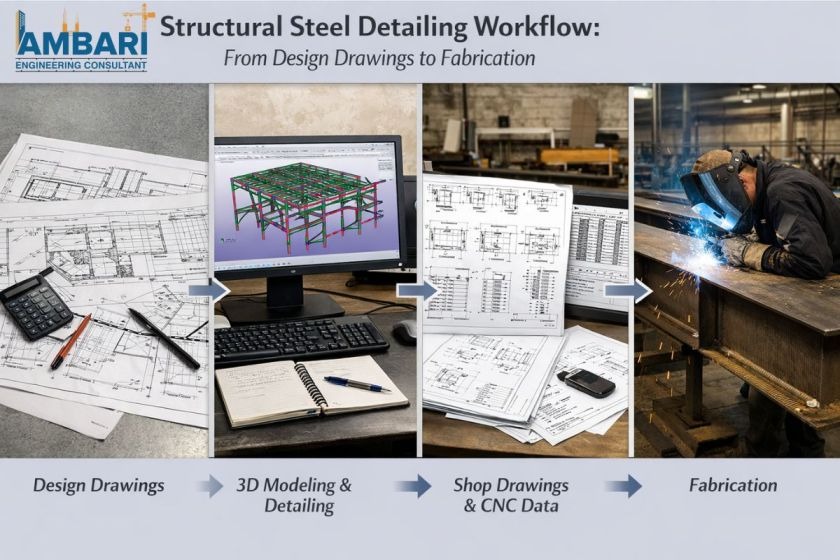

One of the most crucial steps in a steel structure project is structural steel detailing. It is used to bridge the gap between concepts of design and actual construction. Clearly defined and strategically planned workflow can minimize errors, save time, and enhance the safety of the sites.

Moreover, structural engineering services in India are dependent on proper steel detailing to make sure that buildings and structures are strong, secure, and simple to produce in a variety of projects in the country. In this blog, we will describe the entire process of structural steel detailing, including its design drawings to final fabrication.

Steel detailing is not just about making drawings. It focuses on transforming design intent into clear, easy-to-follow instructions that can be understood by fabricators and site teams. As a result, all bolts, welds, plates, and connections are clearly defined.

Furthermore, accurate detailing helps prevent costly changes in later stages. When the workflow is executed step by step, overall project implementation becomes smoother and more efficient.

The project begins with design drawings prepared by structural engineers. These drawings define the overall structure, load information, and member sizes, but they are not yet ready for fabrication.

Additionally, applicable standards and project requirements are reviewed in detail. This step is critical, as any misunderstanding at this stage can lead to major issues later. Drafting and detailing services in India place strong emphasis on this review process to establish a solid foundation for the next phases.

After interpreting the design drawings, the coordination phase begins. Steel detailing is not an isolated activity; it depends on inputs and collaboration from multiple teams.

Coordination goes beyond drawings and also includes project schedules, fabrication limits, and construction methods. All collected data is properly organized before the actual detailing work starts.

This step helps prevent conflicts between steel components and other building materials, ultimately saving time and improving construction efficiency.

Once all the required data is finalized, the actual detailing work begins. Each steel component is clearly represented in detailed steel drawings, commonly known as general arrangement drawings and connection details.

Although advanced software tools are used, the skill and experience of the detailer play a crucial role. Well-practiced detailing results in drawings that are easy to understand and fabricate. Steel detailing services in Vadodara focus on accuracy and clarity, especially in regions with active industrial development, to support faster project delivery.

Shop drawings are prepared after the general steel drawings are approved. These drawings are used directly by fabricators on the shop floor, so they must be highly detailed and precise.

In addition to these details, shop drawings also include material lists and part numbers. Fabrication shop drawing services in Vadodara follow strict checking procedures to ensure drawings meet both design intent and fabrication requirements.

This thorough review process minimizes fabrication errors and significantly reduces material wastage.

Once shop drawings are approved, fabrication begins. Steel members are cut, drilled, welded, and assembled strictly according to the approved drawings.

The quality of fabrication is directly linked to the quality of detailing. Clear and accurate drawings eliminate confusion on the shop floor, while proper labeling supports smooth transportation and efficient onsite installation.

Even with a well-defined workflow, challenges can arise during the steel detailing process. However, effective planning and coordination help manage these issues.

These challenges are addressed through structured practices:

Experienced detailers also add value by suggesting improved connection details and optimized member arrangements, contributing to overall project efficiency and success.

Structural steel detailing workflow is important to transform design concepts into robust and durable structures. All the steps must be considered and coordinated, starting with the review of design drawings and concluding with the provision of clear shop drawings. The workflow can minimize the cost and errors and help to build safely when observed correctly.

Furthermore, most of the structural engineering services in India today depend on the use of skilled detailing teams that facilitate the fabrication and erection. Through organized procedures, effective communication, and thorough inspection, steel detailing is an excellent backbone to successful steel projects.

What is structural steel detailing?

Structural steel detailing converts design drawings into clear fabrication guidelines for accurate manufacturing and assembly.

Why is coordination important in steel detailing?

Coordination helps avoid conflicts, reduces errors, and ensures smooth workflow between design, detailing, and fabrication teams.

What are fabrication shop drawings used for?

Fabrication shop drawings guide cutting, welding, drilling, and assembly activities on the fabrication floor.