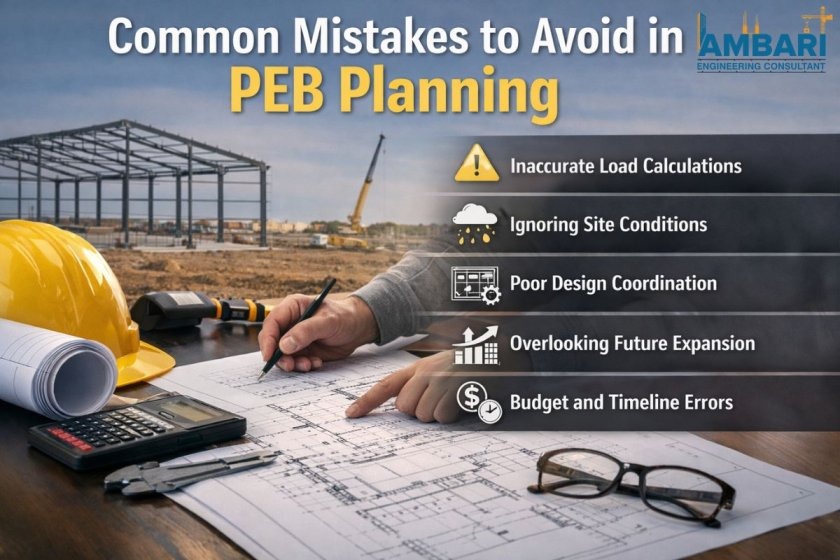

The most frequent errors in PEB planning occur because of the incorrect decisions made at the initial stage. These mistakes add to cost, extend schedules, and shorten building life. Therefore, knowing what not to do in pre-engineered building planning will save money, time, and future stress. This guide presents real-life experience in the industry.

At Ambari Consultant, the PEB projects are planned with clarity, technical knowledge, and long-term value in mind. Furthermore, proper planning prevents duplication of work and makes the process smoother.

PEB planning determines the strength, safety, and cost-effectiveness of the building. Even though pre-engineered buildings are quicker to construct, planning errors may eliminate all these benefits.

Additionally, PEB design and detailing services in India assist in matching the structure, load, and use at the initial stage itself and minimizing the risks in the future.

One of the greatest errors in PEB planning is to ignore the conditions of the site. Each site possesses varying soil strength, wind speed, seismic area, and drainage characteristics.

Problems that are common with bad site analysis:

Nevertheless, most project owners do not conduct appropriate soil testing in order to save on money. This temporary saving is later translated into high repair expenses. However, a site study should be carried out at all times prior to finalizing the layout.

At Ambari consultant, site data is scrutinized to prevent such hidden risks to provide accuracy in the design.

The design of a PEB is believed to be easy by many. But improper design decisions cause severe issues in the fabrication and construction.

Poor design leads to:

Despite the fact that there are a number of pre-engineered building manufacturers in India that provide standard designs, each project requires customization, depending on its use, climate, and future intentions.

Furthermore, design must not be duplicated in the past projects. It should be site-specific and purpose-based in order to prevent wastage and failure.

The choice of materials is a significant factor in the construction of performance. The second mistake is to choose the cheaper materials without considering the quality standards.

Issues with incorrect materials:

However, roof sheets, bolts, paint systems, and insulation should be in accordance with the environment. Special material planning is needed in coastal, industrial, and high-temperature regions.

Therefore, smart material choice enhances safety and minimizes cost in the future.

Inaccurate estimation causes financial strain in execution. Most projects begin with approximate cost estimates, which are later transformed radically.

Errors in estimation are:

Precise Pre-engineered building estimation in India will assist in keeping the cash flow and prevent work stoppage. Additionally, it also helps in the negotiation of vendors and scheduling of the project.

At Ambari consultant, estimation is treated as a technical task, not guesswork.

The fabrication planning determines the ease with which the structure will be put together at the site. Delays and mistakes are brought about by poor planning.

The typical fabrication errors:

Moreover, professional pre-engineered building fabrication in India is a process that is closely checked in terms of quality, attracting coordination and discipline of time.

As such, fabrication must never be done after design but must be planned.

It is dangerous to select vendors simply because of low prices. The wrong choice of vendors is the beginning of many planning failures.

Problems of bad vendor selection:

Nevertheless, reliable suppliers can provide technical advice, compliance assistance, and knowledge of how to work on complicated projects.

This is the reason why an Ambari consultant pays attention to the capability of the vendor rather than the quotation value.

A lot of buildings require expansion after several years. This is, however, not considered in the initial planning.

Issues that no expansion planning causes:

Therefore, expansion may not be an immediate thing, but planning it at design will save on the cost in the future. Bay spacing, column capacity, and foundation strength, therefore, must support growth.

PEB planning is associated with design coordination, accuracy of estimation, control of vendors, and tracking of execution. Lack of professional advice will mean that errors will be detected too late.

Risks of no expert involvement:

Experienced consultants are not only theoretical but also knowledgeable about the real project. In addition, they serve as a mediator between the client, the designer, and the fabricator.

This is where Ambari consultant adds value by ensuring planning decisions are practical and technically sound.

It is easy to avoid the common PEB planning mistakes by making early and careful decisions. Expert planning can avoid poor site study, wrong design, weak estimation, and errors by vendors. Ambari consultants will guarantee safe, rational, and future-proof PEB buildings that are more durable and less expensive.

What is the biggest mistake in PEB planning?

Ignoring site conditions and future needs creates serious long-term problems.

Is estimation important in PEB projects?

Yes, proper estimation will eliminate budget overruns and delays in execution.

Can poor design affect building safety?

Yes, improper design will have a direct influence on load capacity and life.